Innovation in aluminum die-castingGas injection molding

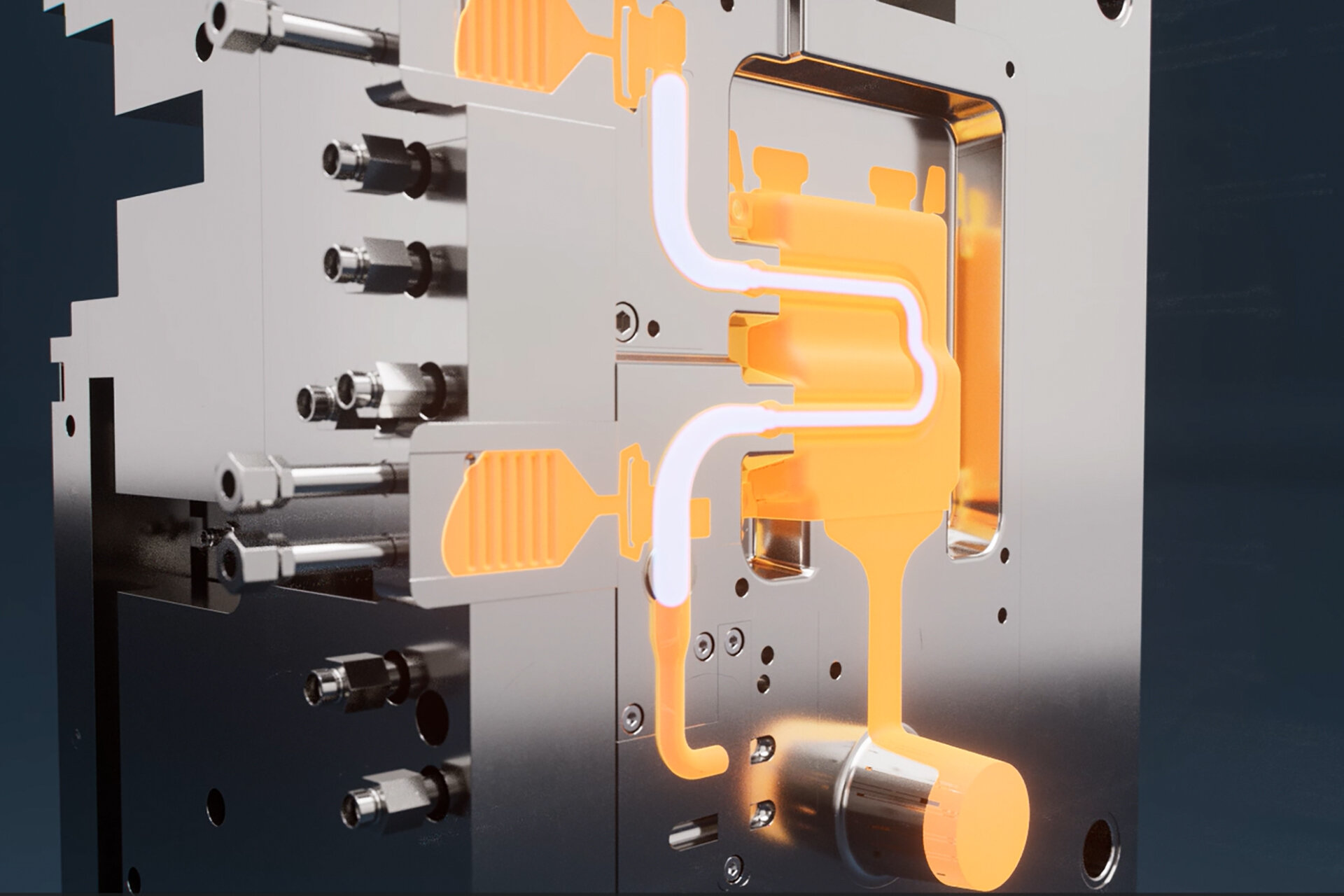

The gas injection molding process opens up new horizons in aluminum die-casting. This innovative method makes it possible for the first time to form cooling channels during the casting process. This step takes place after completion of the mold filling phase and at the beginning of the cooling phase of a component. The penetration of a gas needle into the already solidified surface layer of the component and the immediate injection of a gas under high pressure displaces the still liquid melt in the core of the component into an opening overflow. This creates a defined cavity that can be produced without additional upstream or downstream processes.

The gas injection molding process in the automotive industry

The gas injection molding process is attracting growing interest in various sectors, particularly in the aerospace industry. Another important area of application is the automotive industry. The diverse possibilities are evident, for example, in housings for power electronics in the field of electromobility, in structural components in lightweight construction or in all add-on parts that require media-carrying lines for cooling.

ADVANTAGES OF THE NEW TECHNOLOGY

- Production of complex cavity geometries

- Cost-effective production

- New design possibilities

- Lower weight

To the complete BOCK range of services: