BOCK ChinaStandard products or according to individual customer requirements

Our local partners and customers can rely on short communication channels and our entire know-how through our subsidiary in Dongguan, Guangdong. With our international network and the BOCK range of services, we are experts in the OFFICE area.

The complete range of services of the BOCK Group

An international management and approx. 400 employees will do everything possible to implement the wishes and needs of our customers to their complete satisfaction. Our range of services extends from research and development and our own tool shop to the processing of plastic and aluminium and the assembly of individual components. Our service is rounded off by our quality assurance, which meets high international standards. With over 50 years of experience in the BOCK Group, we are able to successfully implement standard products or customer-specific projects.

the entire spectrum What we do

01Research & development

In close cooperation with our main location, we invest a large part of our capacities in the area of research and development, thus laying the foundation for the subsequent success of customer projects. Based on the requirements, we develop innovative concepts and products that meet the needs and wishes 100%.

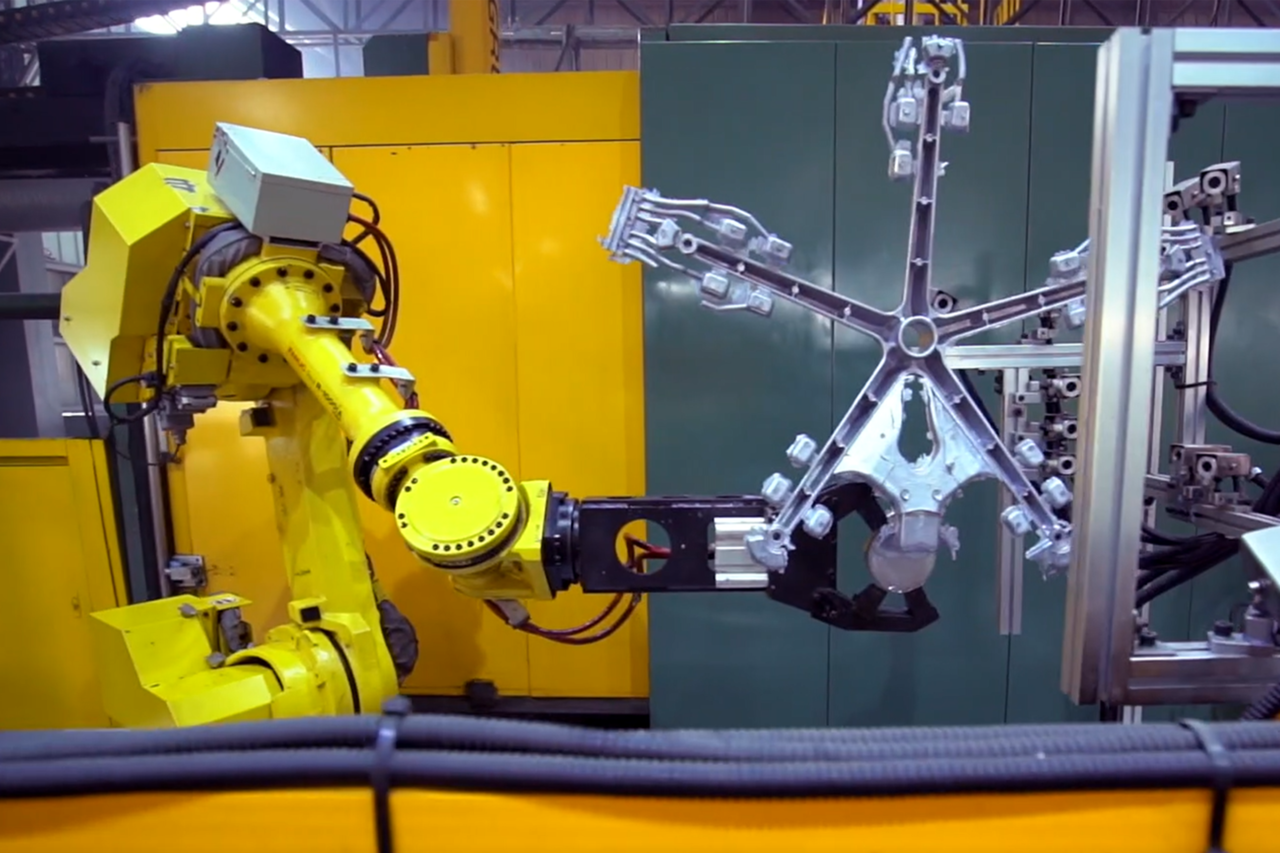

03 Production

The know-how in plastic injection molding built up over more than 50 years offers BOCK customers real added value. Our machinery includes 5 plastic injection molding machines ranging from 80 t to 700 t and is suitable for producing all types of furniture parts, including those made of glass fiber reinforced material (GB/GF). With our on-site die casting expertise and the support of our die casting team at the main location, we have our own "Center of Competence Die Casting" (COCDC). Our service is made possible by 11 die casting machines ranging from 420 t to 1000 t, 3 central ovens and transportable melting ovens that can cast different materials simultaneously. After additional cleaning of the materials by our degassing system and with the dimensional accuracy of our 3- or 4-axis CNC machines, we mill and drill the aluminium into the desired shape and texture. We also have the equipment to grind and polish the components to a high quality.

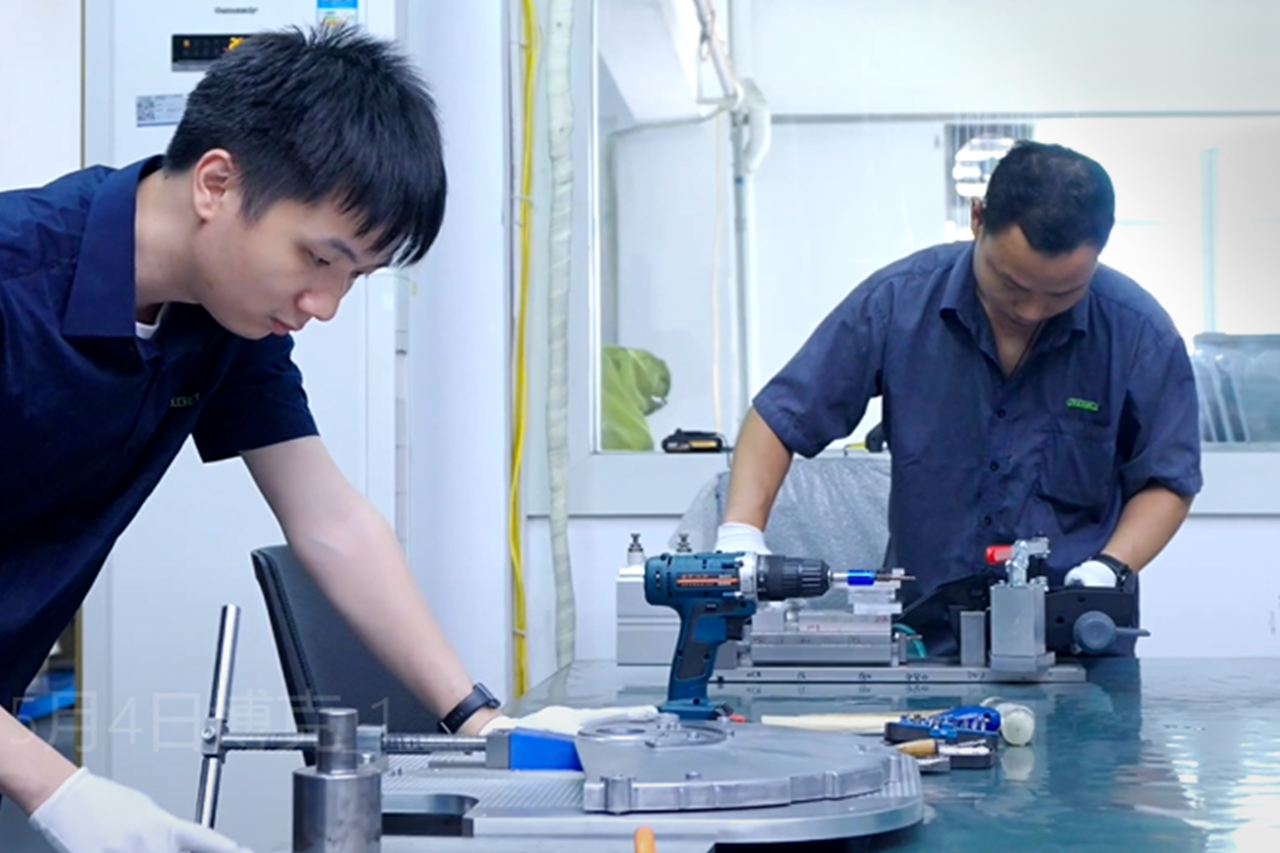

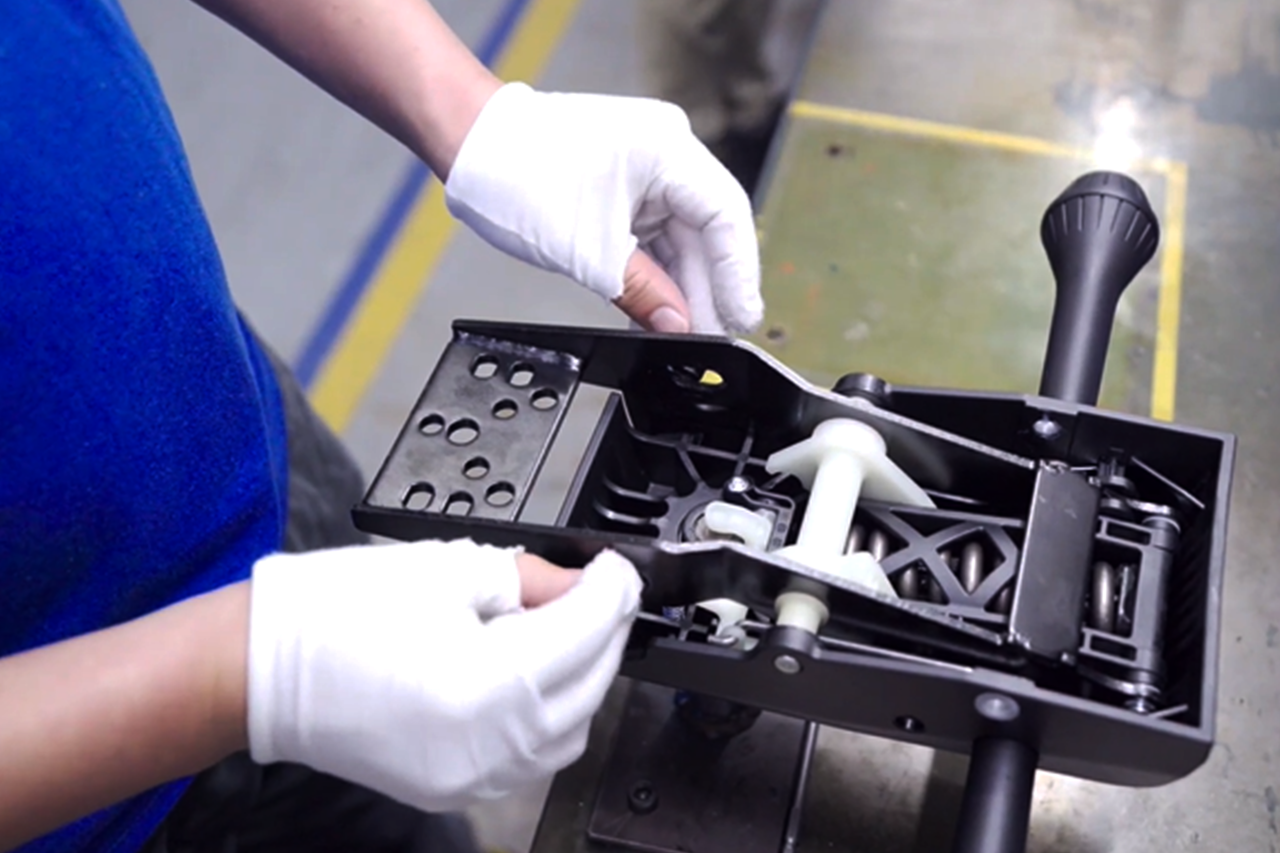

04 Assembly

BOCK China undertakes the assembly of standardized and customized BOCK products. In this process, we perform quality checks on functionality and appearance to ensure that all components meet our customers' requirements.

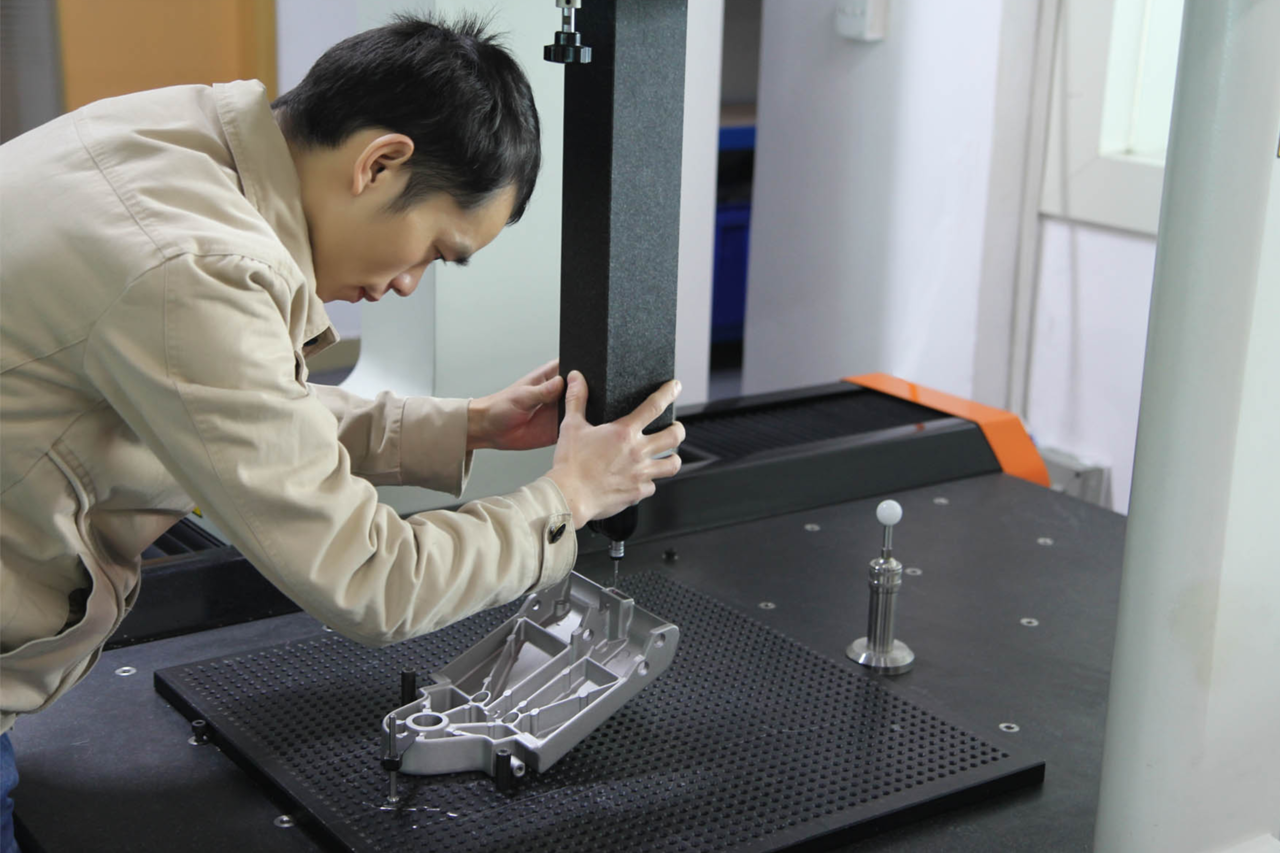

05Quality assurance

Our quality assurance is confirmed with the ISO 90001 - certificate of the TÜV and thus ensures the compliance with the high BOCK quality standard. In addition, we follow the automotive quality system which includes MSA, APQP, SPC, FMEA and PPAP. Our on-site test laboratory has various test methods that examine our complete chairs according to BIFMA and EN. We also carry out breaking tests, endurance tests and color verification, completed with checking raw materials for moisture and mold flow rate.

06Individual product development

A particular strength of ours lies in the individual cooperation with our customers. Our high level of expertise enables us to implement even complicated projects individually according to customer requirements. Our worldwide resources make every order a success.

Data and facts

- International management

- Over 400 employees

- Production on 6 days, 24 hours in 2-shift operation

- Foundation 2009 BOCK China

- Certified according to ISO 90001

- International network in Germany, Canada and Hungary

Impressions

All information about the BOCK Group of companies:

Company